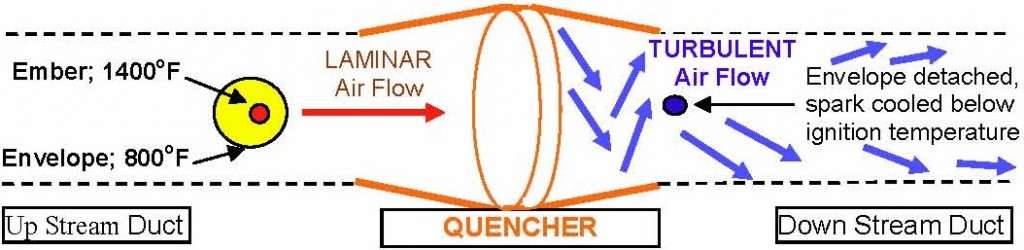

Spark arrestors are proven to prevent fires in dust collectors. One of our engineers discusses the science behind how The Quencher works to stop sparks/embers and prevent fires in your ducts.

Transport of sparks through ducts; Referring to the sketch below, there is a glowing ember (red particle) surrounded by some hot air (yellow envelope) which gives the spark buoyancy. This spark (at approx 1400°F) and the hot gas (at approx 800°F) associated with it can travel hundreds of feet in a duct. The duct work is designed to give laminar (smooth) flow. This is illustrated on the left of the QUENCHER spark arrestor. Spark suppressors are placed in the duct to change the flow to a turbulent (coarse) flow, as shown on the right of the QUENCHER spark arrestor. This agitation or turbulence strips the air from around the ember thereby removing the fuel (oxygen) and breaking up the envelop of hot air, therefore extinguishing and cooling the spark below ignition temperature(pink particle).

Prevention depends on eliminating the causes of ignition.

- Spark arrestors and traps can change laminar to turbulent flow and extinguish any sparks in a duct.

- Design duct systems for dust transport velocities.

- Install a pneumatic actuated duct booster to flush dust into the dust collector.

- Use air jets to remove electrostatic charges on duct surfaces.