Quencher; the original spark arrestor for dust collection since 2004 and is the only one that complies with the NFPA 69 Standard on Explosion Prevention Systems. A passive easy to apply in-line device with no moving parts to fail. An automatic self-cleaning option keeps the spark arrestor clean.

Booster Duct Cleaner; Installing our Booster Duct Cleaner will help boost airflow and clean dust build-up in your ducts. The Booster Duct Cleaner is easy to install and uses advanced pulse jet technology, each cleaner is able to handle 20-50 feet of duct. A Low Cost Simple Solution for Dust Dropout.

Specialists for exclusively retrofitting of existing conventional technology dust collectors to the benefits of new advanced technology. Our expert and vastly experienced engineers will consult for dust collection system design and troubleshoot problem systems. If we can’t fix it, no one can!

Imagine operating the best industrial spark arrestor (trap) to control contaminants and sparks/embers in any industry. Toll Free: 1-800-267-5585

|

Quality Air Solutions Manufacturers of

Spark Arrestor

Spark Arrestor

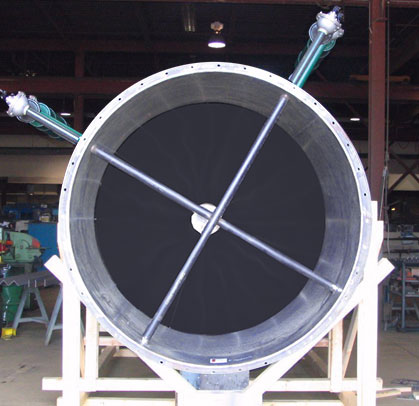

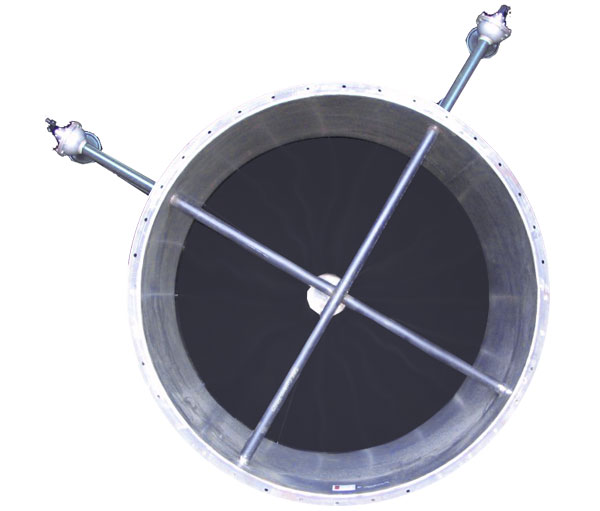

QUENCHER Spark Arrestor

This is the only passive inline spark arrestor that complies fully with NFPA 69 Standard on Explosion Prevention Systems. Quencher is built with uncompromising robust industrial quality, designed specifically for dust collection systems. Since 2004 the Quencher and Mini-Quencher have had unparalleled success since being introduced as the first original inline spark arrestor/trap for the dust collection industry. Many imitators have come and gone of flimsy construction, none of which can or will claim 100 % spark elimination which Quencher does. One spark only getting through can set fire to the dust collector.

Auto Duct Cleaner Booster

This inline Momentum Pulse Cleaner Booster is an easy add-on to existing duct-work; a simple low cost solution to boost a low air flow condition in a ducted industrial ventilation system. It acts like a booster fan at a fraction of the cost and much easier to implement. Prevent dust accumulation, from drop out, in the duct-work which can be a fire and explosion hazard. The powered ejector/ booster increases the duct velocity to approximately 3 times the initial velocity for a short period of time. The short blast of compressed air blows any dust accumulation safely down the duct until it is capture by the dust filter device (i.e. baghouse).

Testimonials

Our Work

All Quality Air Management products are manufactured, to the highest standards, strictly in the USA and Canada: