Your Ultra-Flow Baghouse Dust Collector will allow you to process large amounts of dust laden air and return perfectly clean air to the work environment, because of the most advanced UNIQUE self-cleaning technology, using powerful, but gentle reverse blasts of compressed air, to inflate the filter bags, causing the dust caked on the outside of the bag to drop down into the hopper. Our top of the line dust collectors can filter out the smallest and largest sized dust particles in continuous operating mode. Our top load filter bags and easy access doors make maintenance as simple as possible.

Your Ultra-Flow Baghouse Dust Collector will allow you to process large amounts of dust laden air and return perfectly clean air to the work environment, because of the most advanced UNIQUE self-cleaning technology, using powerful, but gentle reverse blasts of compressed air, to inflate the filter bags, causing the dust caked on the outside of the bag to drop down into the hopper. Our top of the line dust collectors can filter out the smallest and largest sized dust particles in continuous operating mode. Our top load filter bags and easy access doors make maintenance as simple as possible.

Eliminates dry dust for woodworking, steel and foundry, smelting furnaces, welding, grinding and polishing, laser/plasma cutting, powder coating, cement and asphalt plants, paper, automotive, rubber recycling, grain and flour dust, food, chemical.

If you could payback the entire purchase price of your dust collector, would you do it? See how thousands of operators have done just that with their operating cost savings.

Features at a glance

- Imagine unmatched 99% efficiency on all types of granular dusts and air pollution control at an affordable purchase price

- Lowest Operating Cost and least maintenance (50-70% lower than conventional designs)

- Exceeds OSHA, EPA, NFPA dust collection and management standards

- Advanced pulse jet technology prevents wear and tear of filters and cleans 100% of media

- Positive seal system prevents harmful dust leakage to the outlet

- 30-40% smaller foot print with a lower shipping weight

- Designed, Engineered and assembled in USA and Canada.

Download/Print our Catalog and Technical Documents

- Get all the information in the Baghouse Dust Collector Catalog (PDF).

- Your ULTRA-FLOW dust collector Specifications (PDF)

- Imagine a dust collector that pays for itself ; “Free Dust Collector” (PDF)

- Your guide in selecting the correct dust collector; Dust Collector Selection Guide (PDF)

- Your comprehensive Owner’s Manual (PDF)

Advantages Over Conventional Baghouse Dust Collector

- 85-90% of the market, sold by all the big guys.

- Handle most dust loading’s, high temperature.

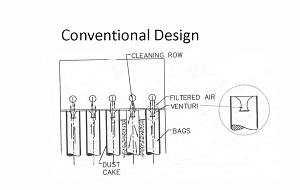

- Circa 1963; compressed air powered cleaning by rows of bags, venturi accelerated the jet to project to bottom of bag, Filter ratio 10:1 or less, dependent on application. Dust penetration (puffing) unacceptable for re-circulation to the work area.

- Circa 1971; “generic” design, modified to use 10 foot bags. Major design flaws let to selection strictly by filter ratio. Most operated at 4-6:1 ratio. Pressure drop is 6-8″wc. High compressed air consumption with higher cleaning frequency.

- High velocity dust impinges on adjacent bags which are too close together.

- The entire industry copied the same design and very little has changed to this day.

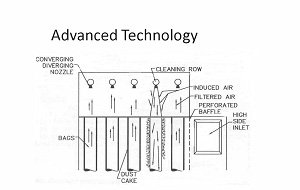

- Ultra-Flow by QAM, circa 2003, are the 6th evolution of the advanced technology.

- Circa 1979; “Advanced Technology” first appeared, Proven technology but little known.

- 95% LESS dust emissions, allows for re-circulation to work area.

- 25-40% lower power consumption.

- 50-80% lower operating and maintenance cost.

- 30-40% smaller footprint.

- No venturi to restrict flow, low velocity – high volume jet = gentle but powerful cleaning pulses = no penetration & complete cleaning.

- 200% increased bag filter life & uses half as many bags.

- HIgh, side inlet eliminates “can velocity”.

- Supersonic nozzles; 1/4 compressed air consumption.

- Runs at 18-24:1 filter ration, independent of process & dust loading.

- Runs at 1.5-3″wc(max) pressure drop.

| Legend | Ultra-Flow | Conventional Baghouse |

| Dust Emissions | 10 x10-5 gr/ft3 (98% less) | 800 x10-5 gr/ft3 |

| Operating Pressure Drop | Only 1.5 to 2.5 inches WC | 4 to 8 inches WC |

| Fan Power | 50 HP (33% lower) | 75 HP |

| Compressed air consumption | 2.5 SCFM (70% less) | 8.0 SCFM |

| Filter bag life | 60+ months (67% greater) | 36 months |

| Foot Print | 68 sq.ft. (37% smaller) | 108 sq.ft. |

| Weight | 7700 lbs | 9480 lbs |

Why you should buy from Quality Air Management

Why buy from us?

Purchasing an Ultra-Flow baghouse dust collector through Quality Air Management means that you are getting the best product by a company that prides itself on the number of installations we have helped clients with their dust collection issues. Since the early 1980’s, our technology has been used in thousands of successful jobs around the world.

- Our Ultra-Flow baghouse dust collector forms a highly efficient filter cake, allowing operation at up to 18:1 filter (air-to-cloth) ratio compared to conventional designs operating at 4-6:1 filter ratio

- No dust penetration (puffing) during cleaning pulses means absolutely clean air returned, allowing re-circulation to the work area without after filters

- The high side inlet acts as a dropout chamber to absorb heavy, abrasive and impulsive dust loading

- Supersonic nozzles on the pulse pipes produce 3.6 times more cleaning energy for every pulse jet; therefore 1/3 the cleaning frequency and 65% less compressed air consumption

- Only 25% of filters are sent to the landfill; uses half of the filter elements with at least 2-3 times longer filter life, compared to conventional designs

Still need more convincing?

Our products were designed with the end users in mind, so they offer several ease-of-use upgrades over competitive models:

- Easy to service: top load filter bags, without being exposed to dusty filter compartment

- Built to ISO 9001:2008 and CWB Certification

- 25-45% lower power consumption and compressed air usage

- 50-70% lower maintenance and operating cost

- 3-5 times longer filter life, 1/2 the number of filters and cleaning hardware

Case Study: Ultra-Flow, Difficult Job

Treadcraft, Ultra-Flow model 60VS-5, B-series advanced technology baghouse

dust collector; collecting rubber, metal shavings and fiberglass fibers from

hammer mills in a tire recycling plant, a very tough application. A Quencher spark

arrestor protects sparks, generated by the hammer mills, from setting the collector

on fire.

Case Study: Ultra-Flow B-Series

Radiac Abrasives, Ultra-Flow model 60VS-8, B-series advanced technology

baghouse dust collector; collecting fine powdered glass, aluminum and resin from

grinding and polishing operations. No after-filter is needed to recirculate air to the

plant which is unique to Ultra-Flow collectors.

Dust Collector Fires

Dust collector fires and explosions are a serious and common occurrence. Protect

your investment with QUENCHER the only NFPA 69 compliant in-line spark arrestor.